SPRINKLER ACCESSORIES

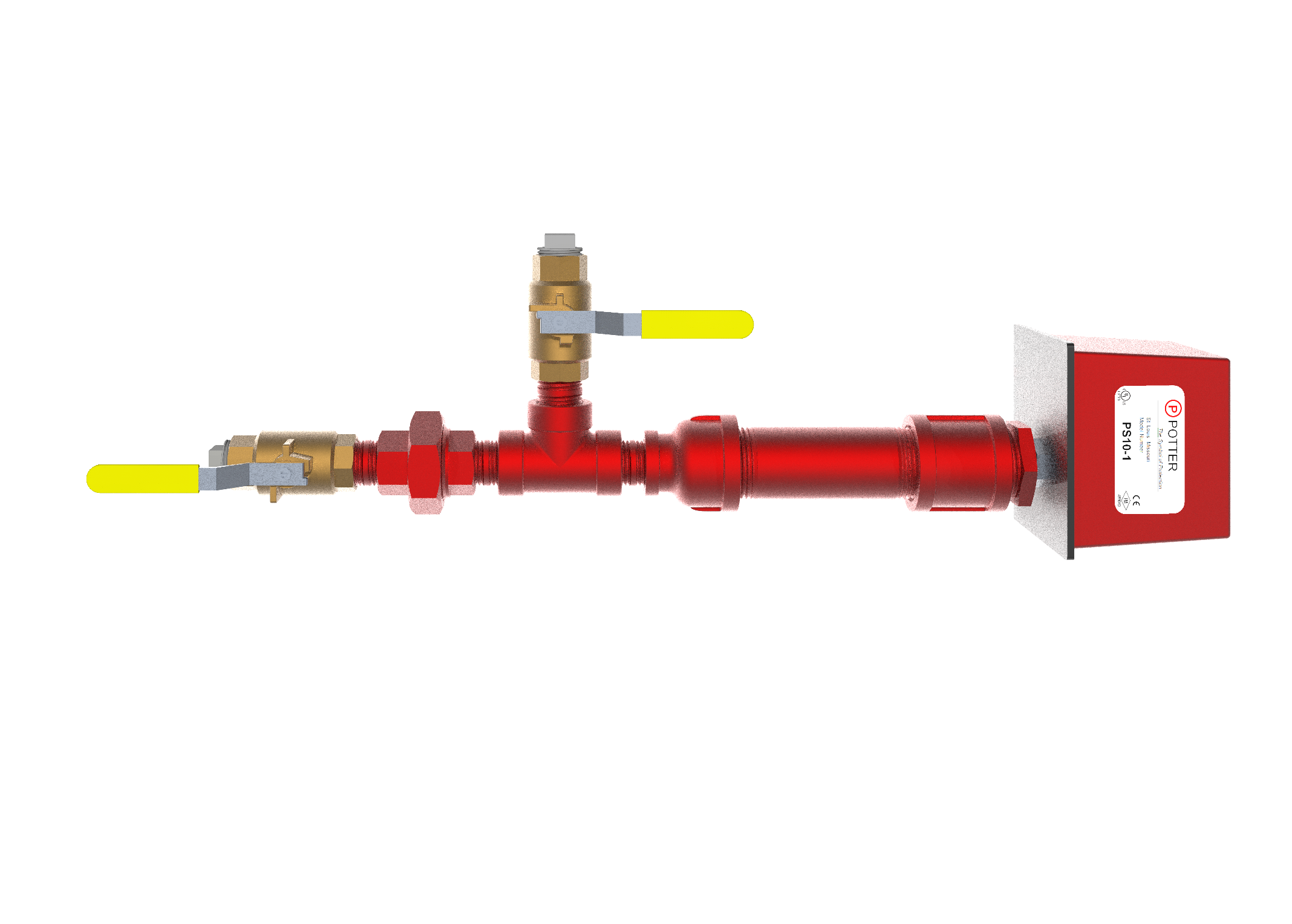

CORROSION MONITOR ASSEMBLY

The UNITED Fire Systems CMA-1 is a device for monitoring the possible corrosion inside of a wet or dry sprinkler system piping. The assembly consists of a corrosion probe in a chamber, a pressure switch, an isolation valve, and a drain valve. The corrosion probe keeps pressure from reaching the pressure switch. When corrosion perforates the probe, pressure reaches the pressure switch, actuating a signal and providing early warning of possible corrosion inside the piping. The isolation valve allows replacement of the corrosion probe without depressurizing the entire system, and the drain valve safely vents pressure from the probe chamber.

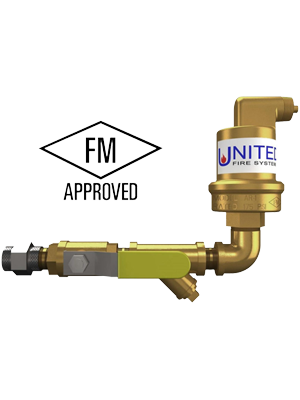

AIR VENT FOR WET SPRINKLERS

The FM Approved United Fire Systems Model AR-1 Wet-Pipe Fire Sprinkler System Air Vent is a device for automatically releasing the trapped air from the high point(s) of a wet sprinkler system. Trapped air contains oxygen, which, when combined with water, is the primary cause of internal pipe corrosion. This corrosion can lead to pipe blockage, leaks, and pipe failure. The Model AR-1 Air Vent is installed at the system high point(s). Air is vented until water reaches the internal float valve, which automatically closes the device to prevent water release.

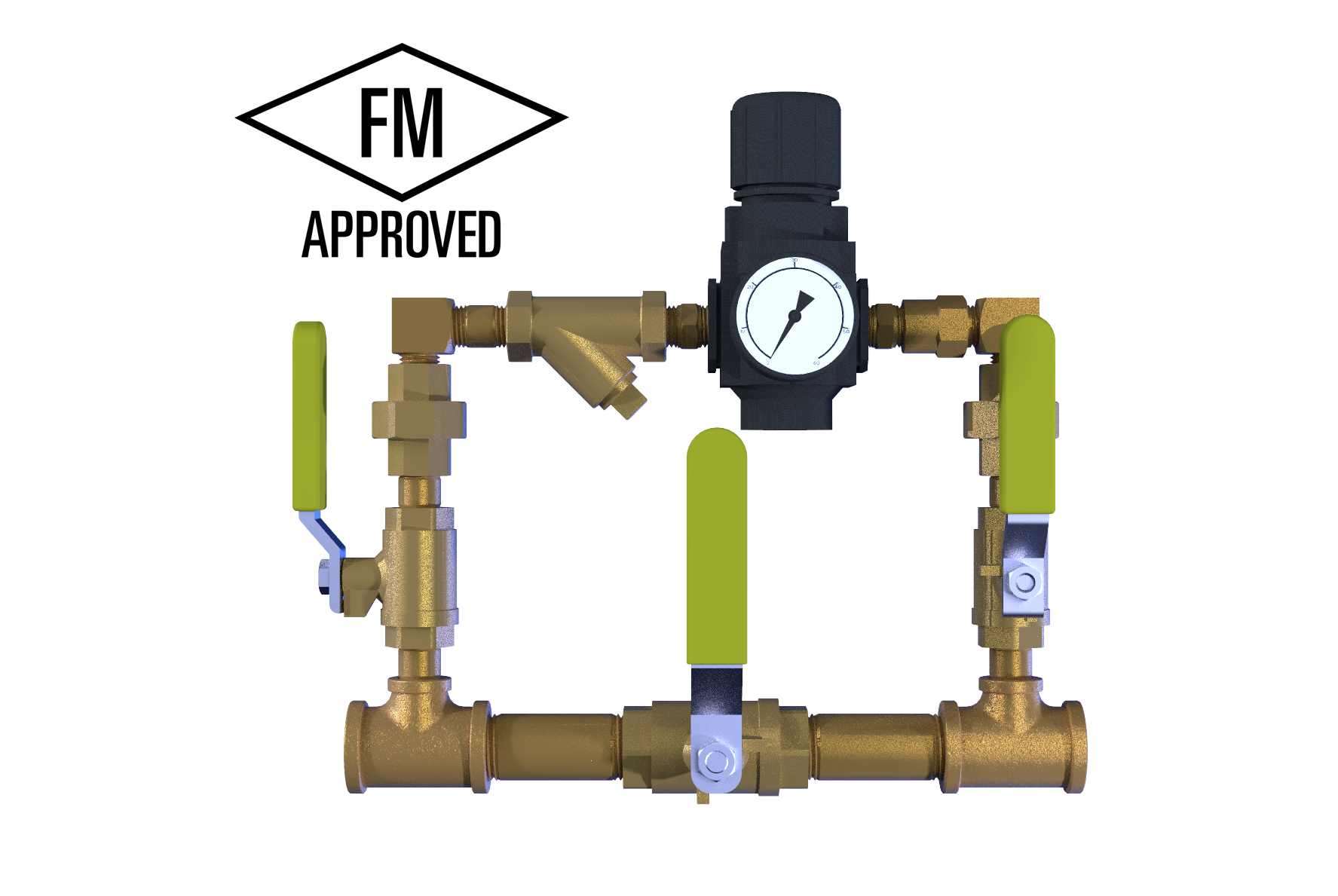

PRESSURE MAINTENANCE DEVICE

The FM Approved UNITED Fire Systems Pressure Maintenance Device Model NAMD-1 is a device designed to automatically regulate and maintain the flow of air or nitrogen into dry-pipe or preaction sprinkler pipe. The air or nitrogen pressure flows through a regulator so that upon activation of a sprinkler head, the air or nitrogen pressure will not interfere with the operation of the sprinkler valve or lengthen the time until the piping fills with water.

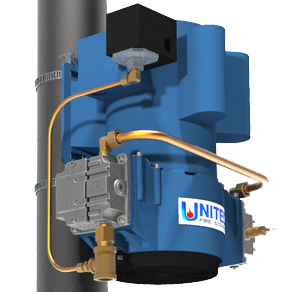

RISER-MOUNT AIR COMPRESSORS

The UNITED Fire Systems Riser-Mount Air Compressor Model RMAC-LP is a device that automatically provides compressed air for preaction fire sprinkler and dry-pipe fire sprinkler systems. These single phase compressors are equipped with an electric motor, oil-less pump, compressor control pressure switch, relief valve, and bracket kit to mount the device directly onto the sprinkler riser above the preaction or dry-pipe valve. It can also be floor- or wall-mounted.