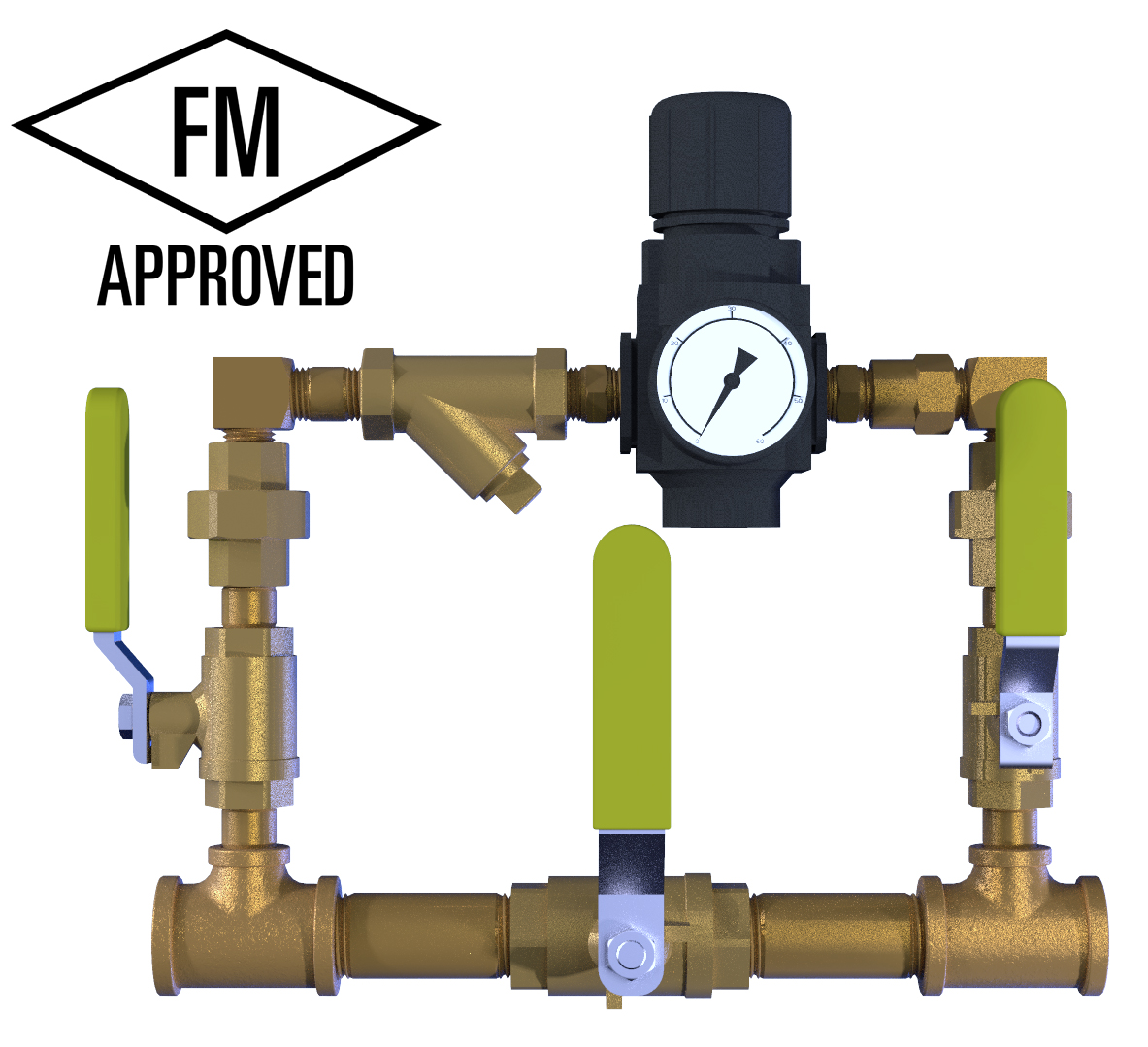

PRESSURE MAINTENANCE DEVICE

The FM Approved UNITED Fire Systems Pressure Maintenance Device Model NAMD-1 is a device designed to automatically regulate and maintain the flow of air or nitrogen into dry-pipe sprinkler systems or preaction sprinkler pipe. The air or nitrogen pressure flows through a regulator so that upon activation of a sprinkler head, the air or nitrogen pressure will not interfere with the operation of the sprinkler valve or lengthen the time until the piping fills with water. Shutoff and bypass ball valves are provided to permit initial-fill of the pipe with air, in accordance with the NFPA 13 mandated time requirement of 30 minutes or less. A “Y” strainer protects the regulator from particulate matter.

The FM Approved UNITED Fire Systems Pressure Maintenance Device Model NAMD-1 is a device designed to automatically regulate and maintain the flow of air or nitrogen into dry-pipe sprinkler systems or preaction sprinkler pipe. The air or nitrogen pressure flows through a regulator so that upon activation of a sprinkler head, the air or nitrogen pressure will not interfere with the operation of the sprinkler valve or lengthen the time until the piping fills with water. Shutoff and bypass ball valves are provided to permit initial-fill of the pipe with air, in accordance with the NFPA 13 mandated time requirement of 30 minutes or less. A “Y” strainer protects the regulator from particulate matter.

Features and Benefits

- FM Approved – Complies with NFPA 13 component listing requirement.

- Designed Specifically For Nitrogen – Provides the accuracy, precision, repeatability, and flow needed for supply of nitrogen. Superior to devices meant for air only.

- High-Precision Pressure Regulator – Balanced design minimizes effect of inlet pressure variation on outlet pressure.

- Pressure Gauge – Included to make adjustment easy.

- Strainer – Helps prevent regulator damage from incoming gas contamination.

- Backflow Prevention Device – Prevents problems caused by pressure changes.

- Large Flow Range – Capable of providing nitrogen to both small and large systems.

- Wide Span – Capable of providing consistent flow over a wide span of inlet pressures – no need for multi-stage regulation.

Contact UNITED Fire Systems Today

Give us a call at 908.688.0300 or contact us online to request more information about our Sprinkler Accessories.

Resources

Data Sheets +-

Engineering Specifications & Drawings +-

For .DWG and .DOC versions of these documents, download our Specification Developer

- Pressure Maintenance Device – Model NAMD-1 – Spec & Drawing Details – DS-NAMD-1 Rev 1.00

- Pressure Maintenance Device – Model NAMD-1 – Short Spec – SS-NAMD-1 Rev. 1.02